SPINEA GEARBOXES www.spineagearbox.com |

||

THE GREAT HARMONY OF POWER AND PRECISION

THE TECHNICAL ADVANTAGES OF SPINEA REDUCER

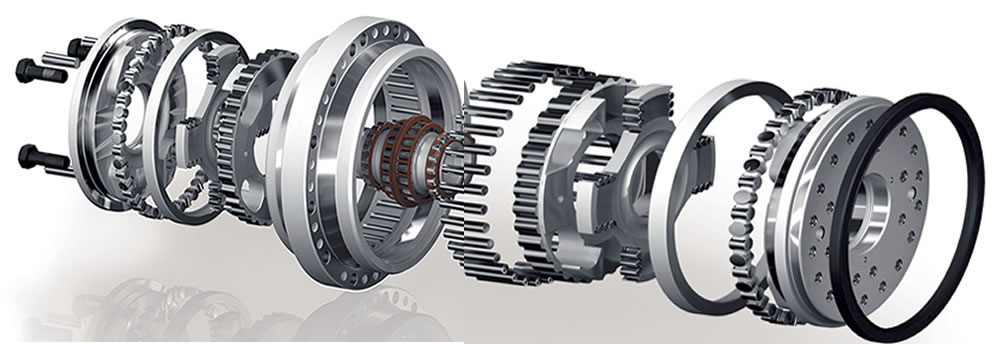

SPINEA PRODUCTS – GEARBOXES AND ACTUTORS ARE BASED ON PATENTED CROSS TRANSMISSION PRINCIPLE WITH INTENGRATED RADIAL-AXIAL BEARING

HIGH REDUCTION RATIO IN SINGLE STAGE

(35-191 depending on size)

- SMALL LOST MOTION (< 0.6 arcmin)

- HIGH KINEMATIC PRECISION

- ZERO BACKLASH

- HIGH AXIAL AND RADIAL LOADING CAPACITY

- HIGH TORQUES AND TILTING MOMENT

- HIGH STIFFNESS

- LOW WEIGHT (from 0.47 kg)

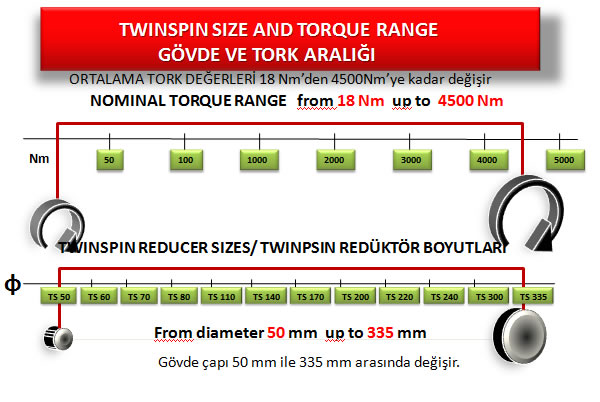

- SMALL COMPACT DIMENSIONS (from diameter 50 mm)

- LOW NOISINESS (< 72dB)

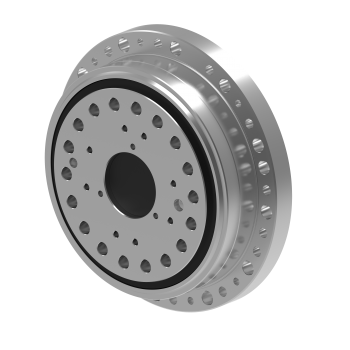

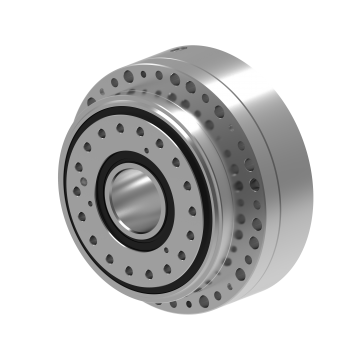

Wide product range - Compactness - Classic version

Spinea General Catalogue, 2019 =>

T Series

T series- represents a wide range of TwinSpin high precision reduction gears with cylindrical shaped case. T Series high precision reduction gears consist of an accurate reduction mechanism and high-capacity radial and axial cylindrical roller bearings. This design of reduction gears allows the mounting of the load directly to the output flange or case without requiring additional bearings. T Series high precision reduction gears are characterized by a modular design, which allows mounting of the reduction gear with your desirable motor type by an inlet flange. T Series shows high precision reduction gears TwinSpin that are not completely sealed, the inlet flange and gasket kit has to be  used for the sealing.

used for the sealing.

T series ordering specifications

T series features

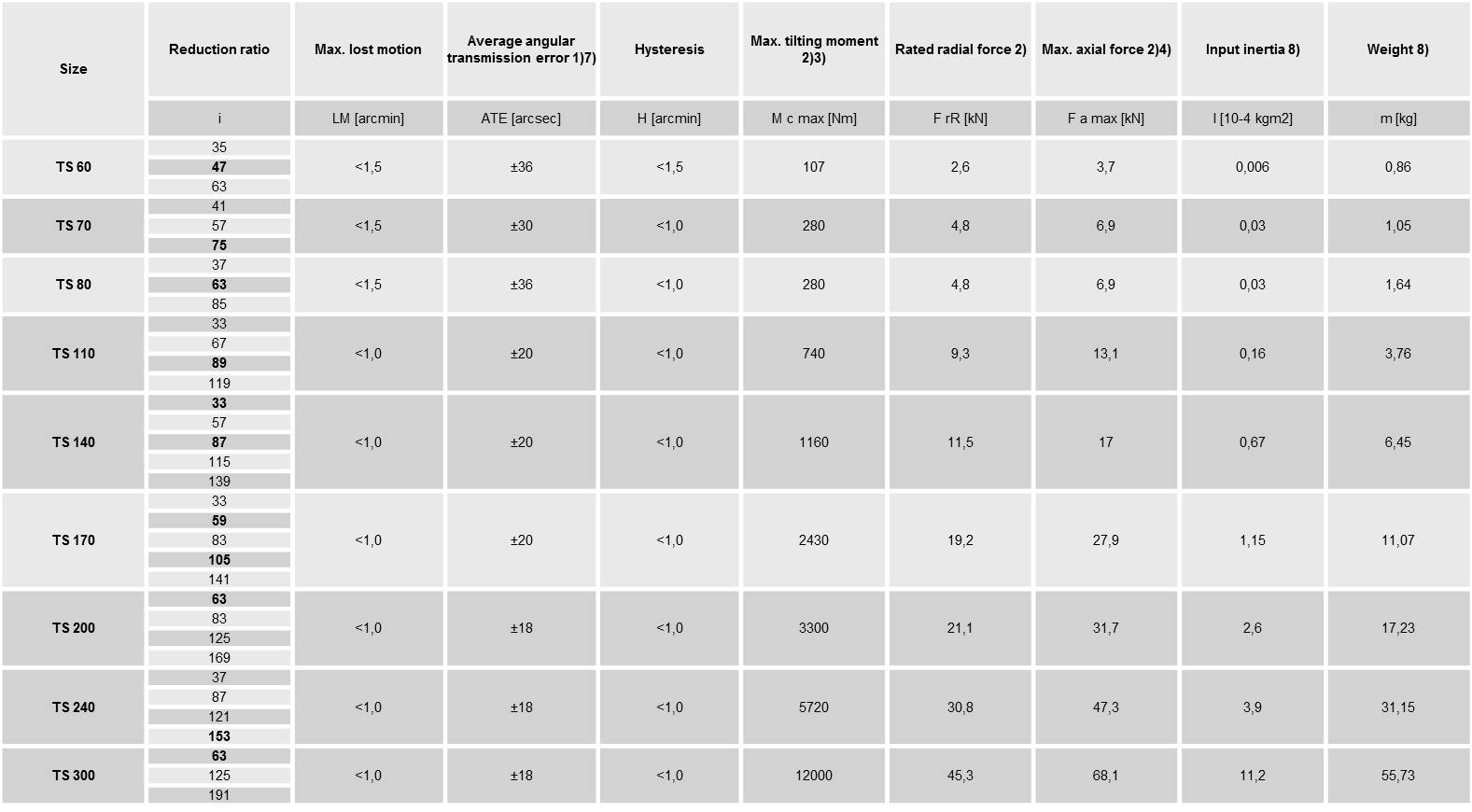

Rating table T series

RIGHT TO CHANGE WITHOUT PRIOR NOTICE RESERVED

1/ Mean statistical value. For further information see chapter Torsional stiffness, Tilting stiffness.

2/ Load at output speed 15 rpm.

3/ Tilting moment Mc max value for Fa=0. If Fa ≠0, see chapter Tilting moment.

4/ Axial force Fa max value for Mc=0. If Mc≠0, see chapter Tilting moment.

5/ The effective speed can also be higher for lost motion bigger than 1 arcmin and for low values of oil viscosity. For lost motion lower than 0,6 arcmin please consult the effective speed with the manufacturer.

6/ The parameter depends on the version of the high precision reduction gear.

7/ The parameter depends on the version of the high precision reduction gear, ratio and lost motion.

8/ The values of the parameters are informative. The exact value depends on the specific version of the high precision reduction gear.

9/ Temperatures of the high precision reduction gear lower than 20°C will cause higher no-load starting or back driving torque.

10/ Depends on the duty cycle; a higher input speed may still be possible; please consult the manufacturer.

Important notes:

• Load values in the table are valid for the nominal life of L10 =6000 [Hrs].

• High precision reduction gears are preferred for intermittent cycles (S3-S8); the output speed in applications is inverted-variable. The continuous mode cycle (S1) is needed to be consulted with the manufacturer.

• Dimensional pictures of the T series reduction gears are listed in the catalogue without sealing.

• Sealing options are described in chapter Assembly instructions.

• Please consult the maximum speed in a duty cycle with the manufacturer.

• The values in the table refer to the nominal operating temperature.

The ratios highlighted in bold are recommended by SPINEA as optimal versions in terms of price and delivery.

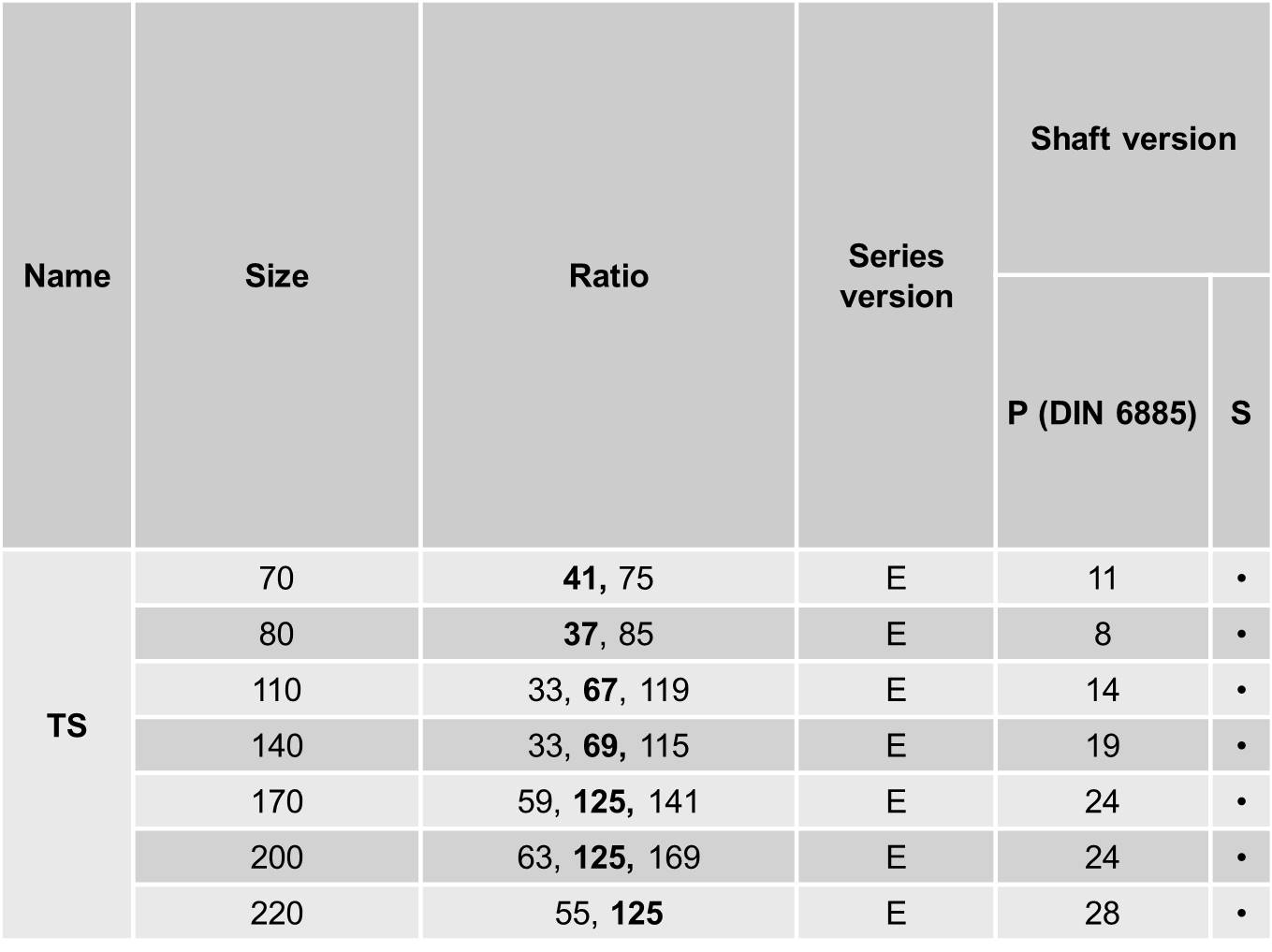

E Series

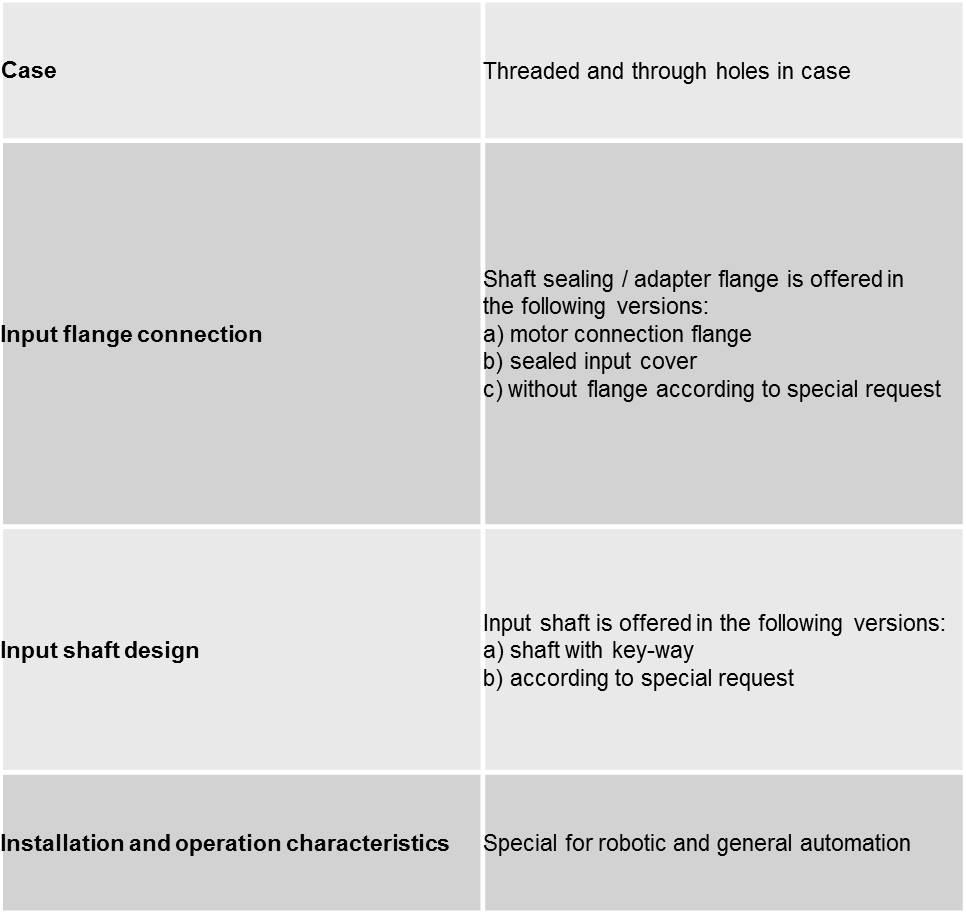

E series-represents a wide range of TwinSpin high precision reduction gears with flange shaped case. E series high precision reduction gears consist of an accurate reduction mechanism and high-capacity radial and axial cylindrical bearings. This design of gears allows the mounting of the load directly to the output flange or case without requiring additional bearings. E series high precision reduction gears are characterized by a modular design, which allows mounting of the reduction gear with your desirable motor type by an inlet flange. E series shows high precision reduction gears TwinSpin that are not completely sealed, the inlet flange and gasket kit has to be used for the sealing.

E series features

E series ordering specifications

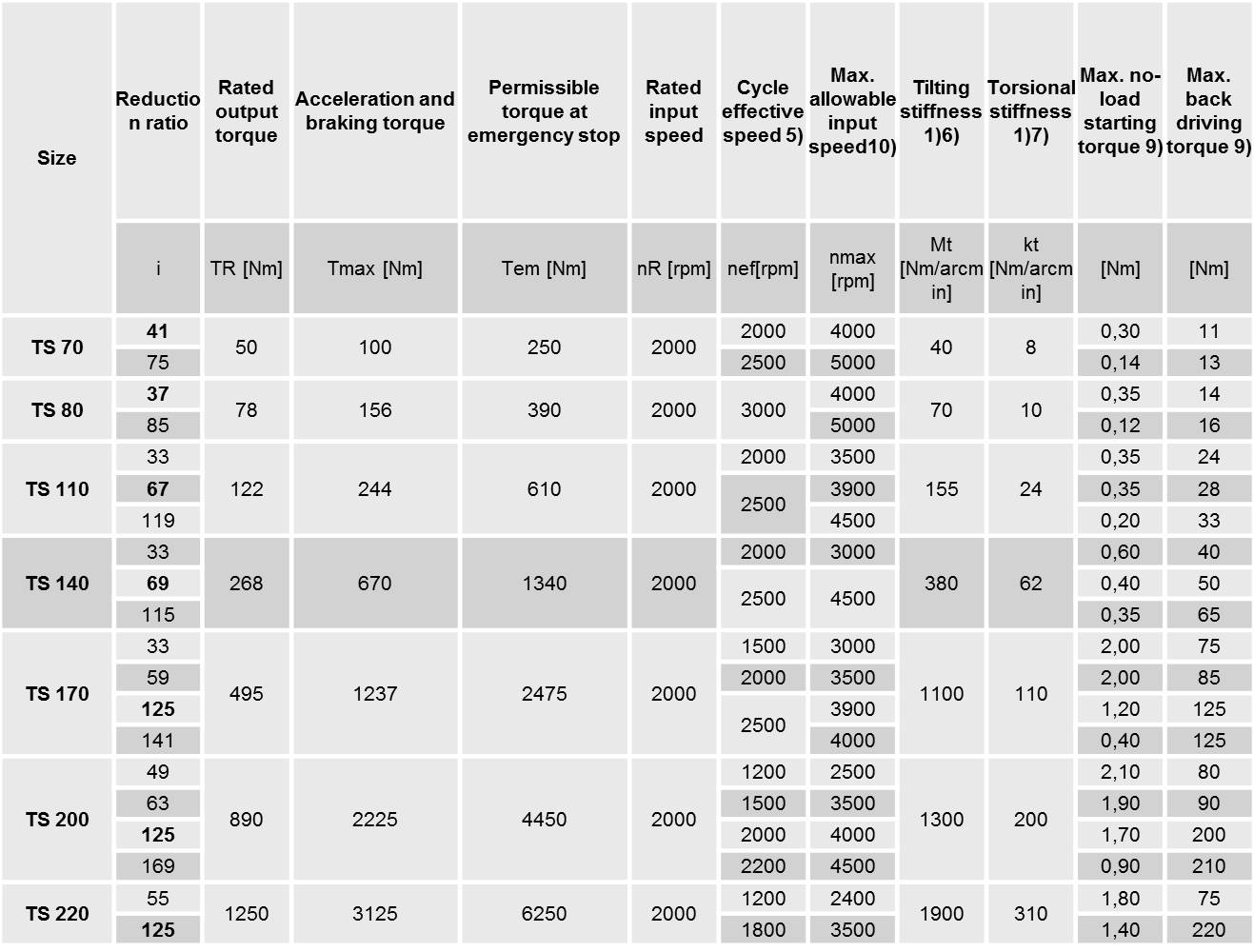

Rating table E series

RIGHT TO CHANGE WITHOUT PRIOR NOTICE RESERVED

1/ Mean statistical value. For further information see chapter Torsional stiffness, Tilting stiffness.

2/ Load at output speed 15 rpm.

3/ Tilting moment Mc max value for Fa=0. If Fa ≠0, see chapter Tilting moment.

4/ Axial force Fa max value for Mc=0. If Mc≠0, see chapter Tilting moment.

5/ The effective speed can also be higher for lost motion bigger than 1 arcmin and for low values of oil viscosity. For lost motion lower than 0,6 arcmin please consult the effective speed with the manufacturer.

6/ The parameter depends on the version of the high precision reduction gear.

7/ The parameter depends on the version of the high precision reduction gear, ratio and lost motion.

8/ The values of the parameters are informative. The exact value depends on the specific version of the high precision reduction gear.

9/ Temperatures of the high precision reduction gear lower than 20°C will cause higher no-load starting or back driving torque.

10/ Depends on the duty cycle; a higher input speed may still be possible; please consult the manufacturer.

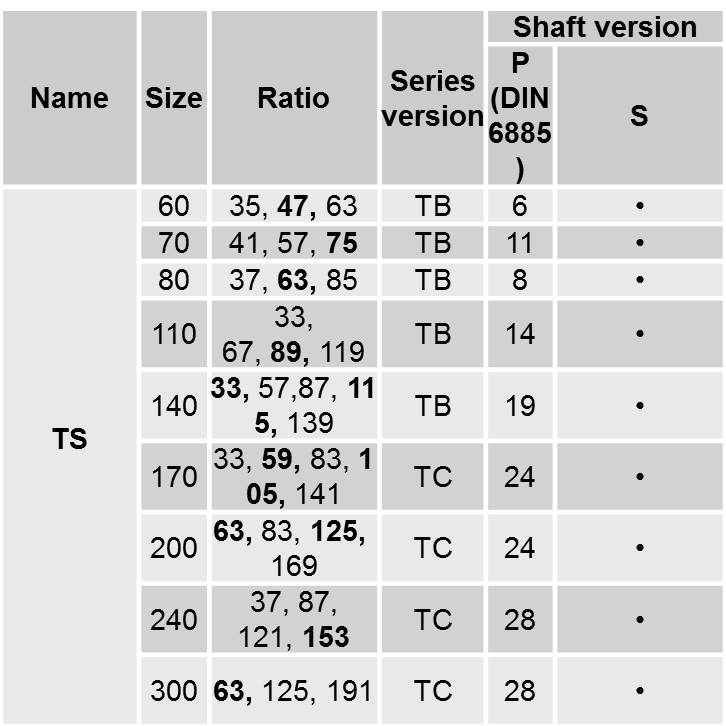

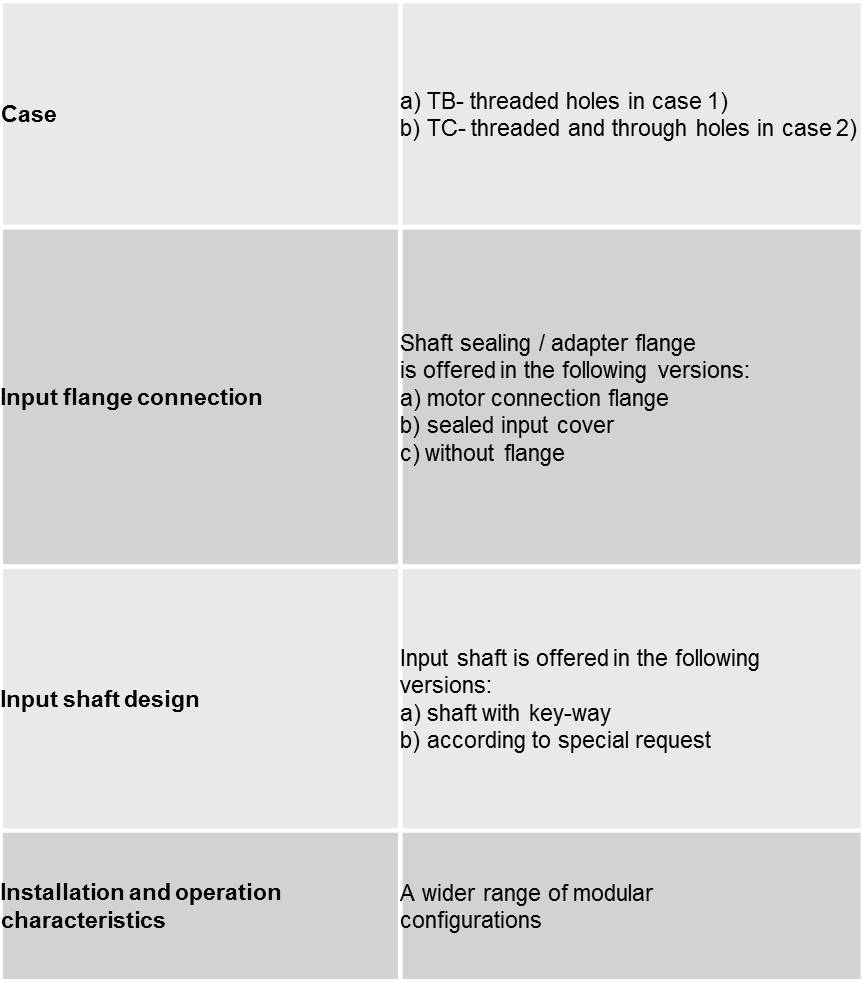

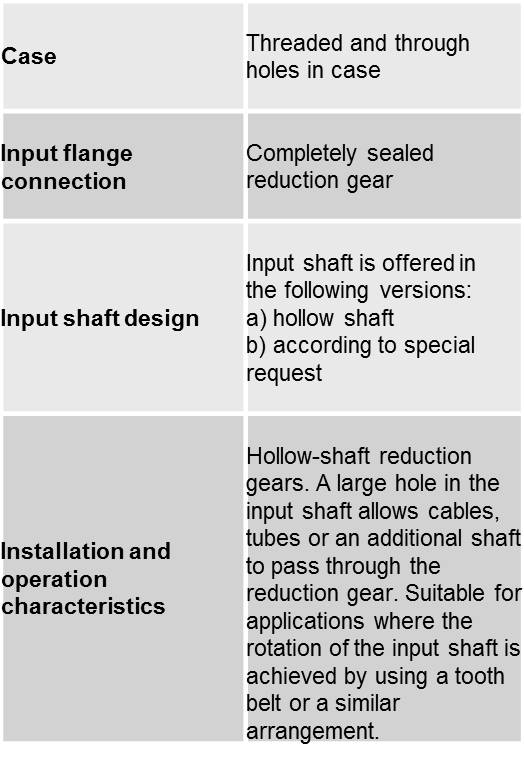

H Series

H series-represents high precision reduction gears TwinSpin with through holes in the shafts, also known as hollow-shaft version. Cables, tubes with compressed air, drive shafts etc. can be led via the through holes in the shaft of the gear. H series is completely sealed and are filled with grease for its lifetime. H series high precision reduction gears consist of an accurate reduction mechanism and high-capacity radial and axial cylindrical bearings. This design of reduction gears allows the mounting of the load directly to the output flange or case without requiring additional bearings.

H series features

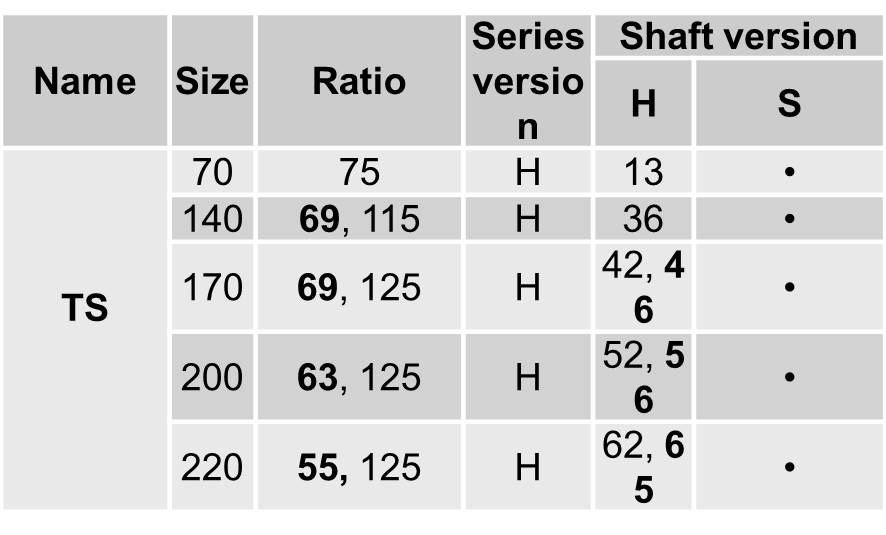

H series ordering specifications

Note: An example of an ordering code of a modified H series TwinSpin reduction gear with a motor flange: TS200 – 125 –H– H56 – M235 – P231. The markings M235 and P231 for a specific modification are defined by the manufacturer.

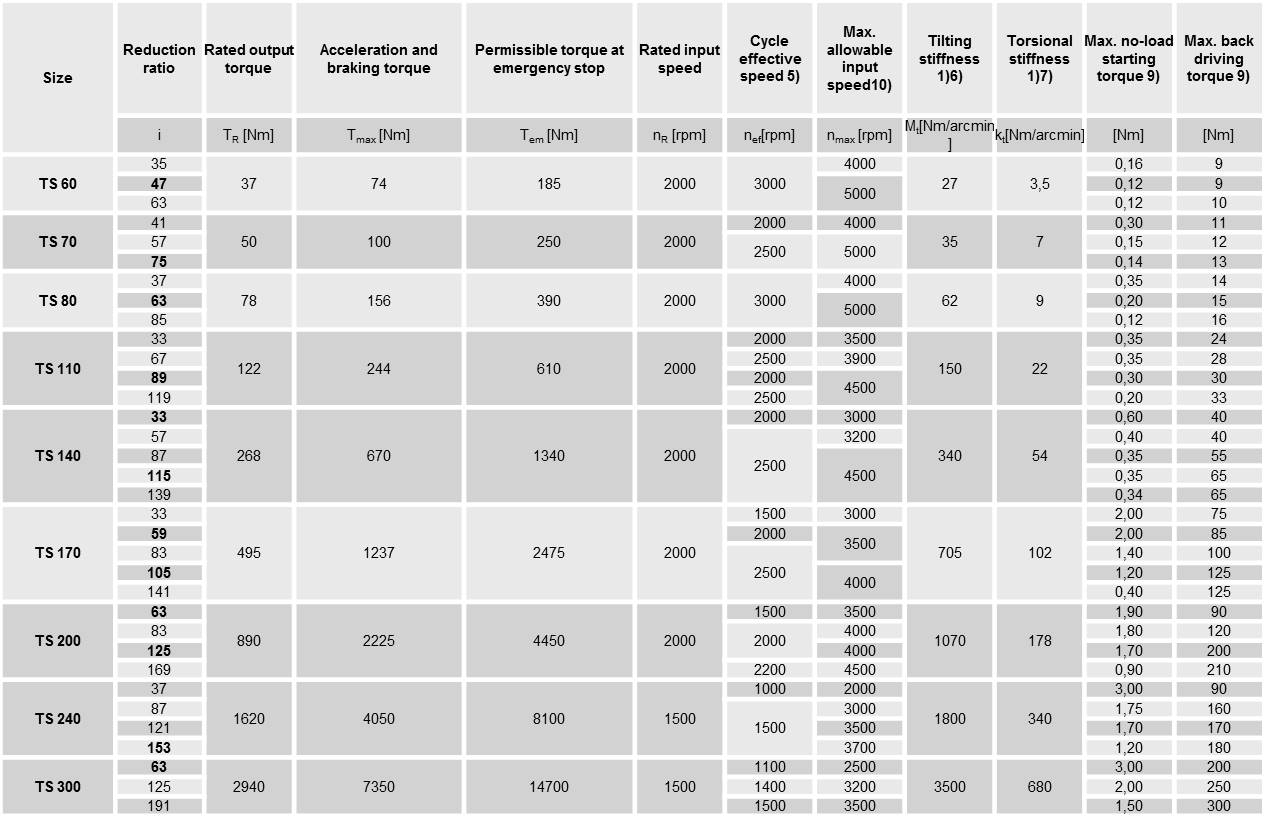

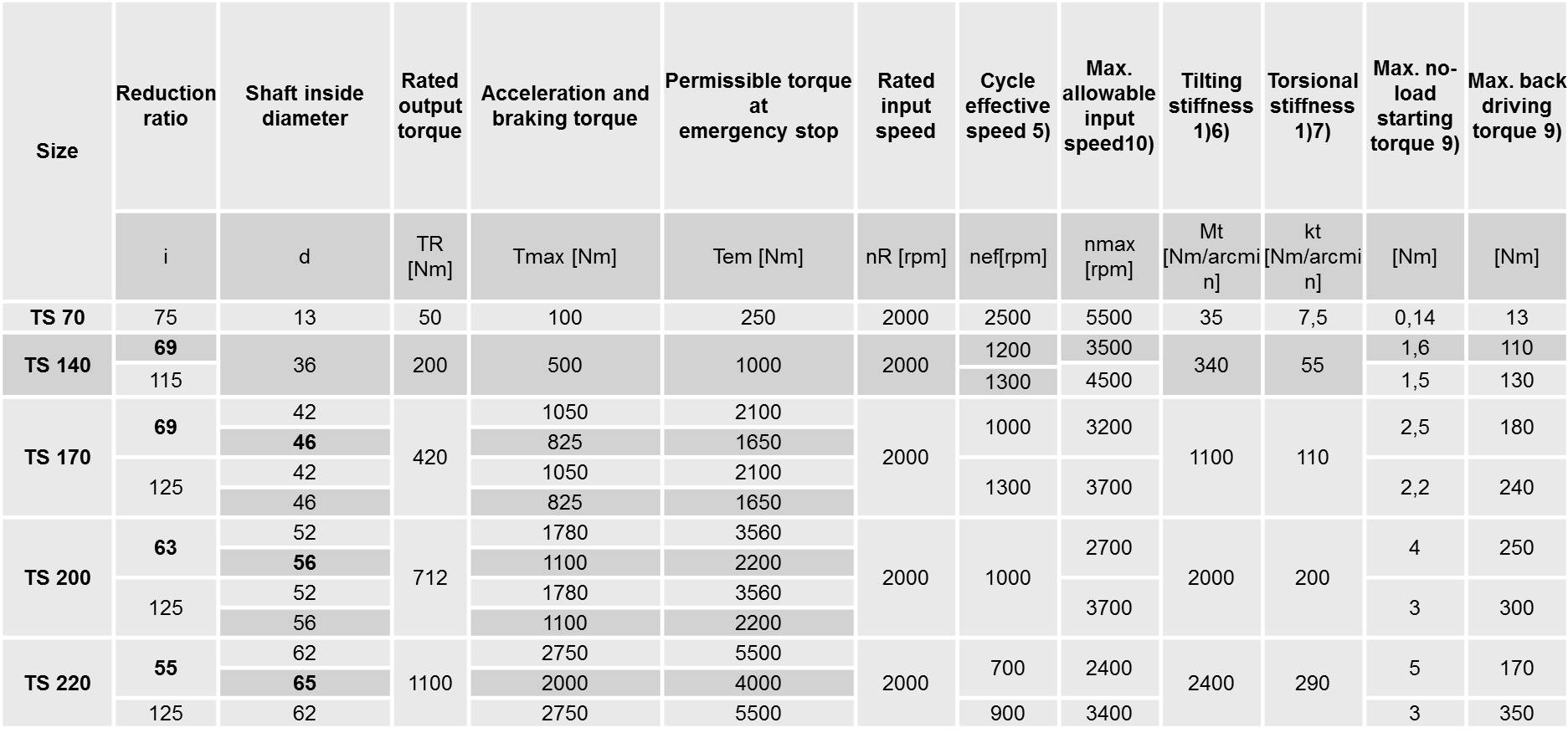

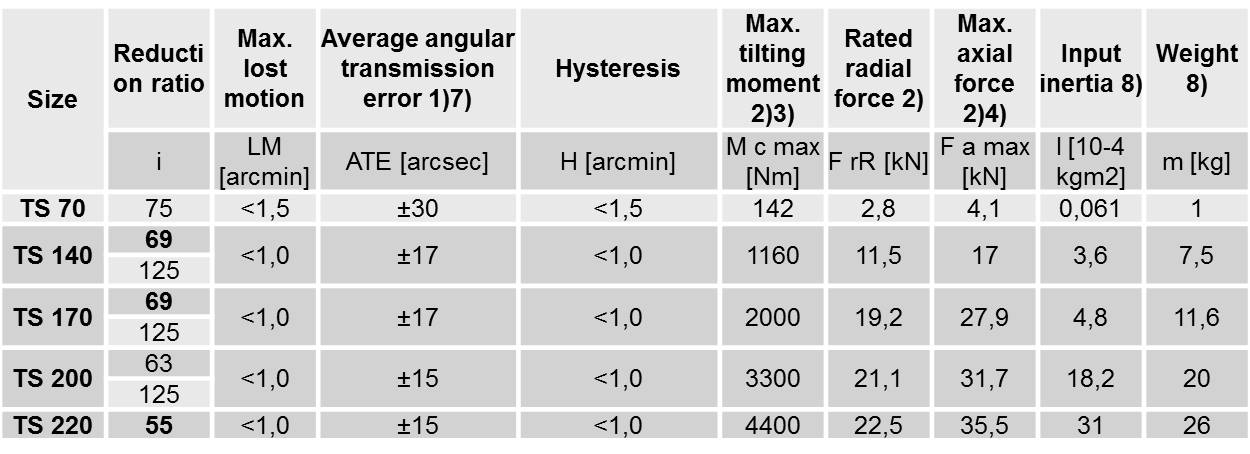

Rating table H series

RIGHT TO CHANGE WITHOUT PRIOR NOTICE RESERVED

1/ Mean statistical value. For further information see chapter Torsional stiffness, Tilting stiffness.

2/ Load at output speed 15 rpm.

3/ Tilting moment Mc max value for Fa=0. If Fa ≠0, see chapter Tilting moment.

4/ Axial force Fa max value for Mc=0. If Mc≠0, see chapter Tilting moment.

5/ The effective speed can also be higher for lost motion bigger than 1 arcmin and for low values of oil viscosity. For lost motion lower than 0,6 arcmin please consult the effective speed with the manufacturer.

6/ The parameter depends on the version of the high precision reduction gear.

7/ The parameter depends on the version of the high precision reduction gear, ratio and lost motion.

8/ The values of the parameters are informative. The exact value depends on the specific version of the high precision reduction gear.

9/ Temperatures of the high precision reduction gear lower than 20°C will cause higher no-load starting or back driving torque.

10/ Depends on the duty cycle; a higher input speed may be still possible, please consult at manufacturer.

Important notes:

• Load values in the table are valid for the nominal life of L10 =6000 [Hrs].

• High precision reduction gears are preferred for intermittent cycles (S3-S8); the output speed in applications is inverted-variable. The continuous mode cycle (S1) is needed to be consulted with the manufacturer.

• Sealing versions are described in chapter Assembly instructions.

• Please consult the the maximum speed in a duty cycle with the manufacturer.

• The values in the table refer to the nominal operating temperature.

The ratios highlighted in bold are recommended by SPINEA as optimal versions in terms of price and delivery.

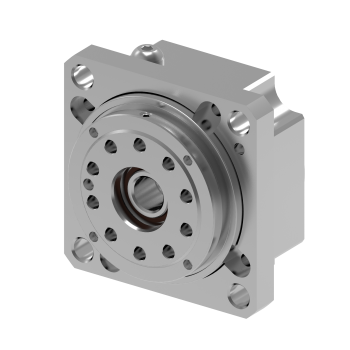

M Series

M series-represents high precision reduction gears TwinSpin of mini sizes. The first representative of the series is the size TS 50, and in the near future we plan to introduce even smaller TwinSpin gears that extend the M series.M series has retained all the qualities of the larger Spinea gears.M series includes a completely sealed gears and are filled with grease for long lifetime. This design of reduction gears allows the mounting of the load directly to the output flange or case without requiring additional bearings.

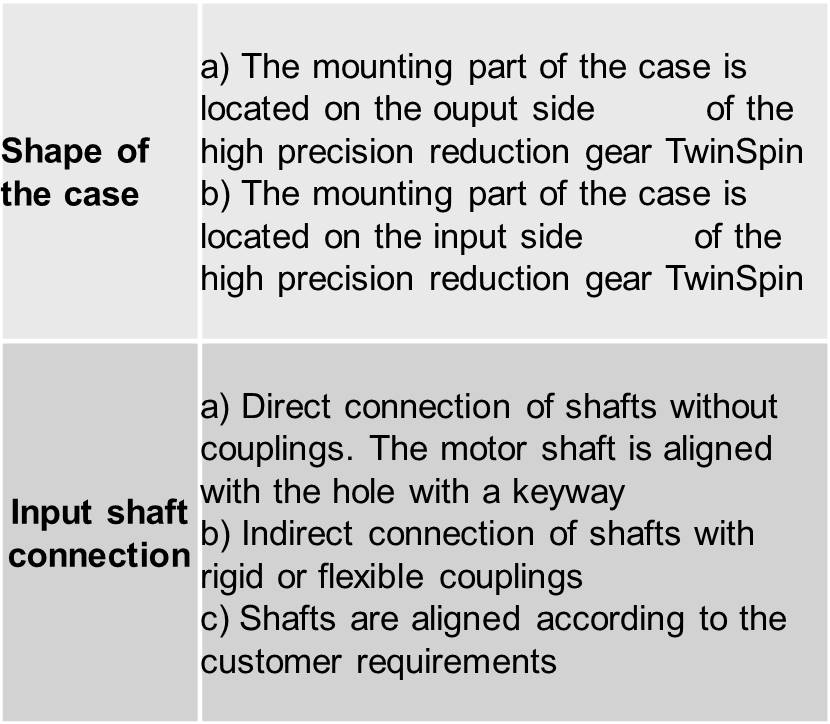

TwinSpin M series mini reduction gear versions

The M series high precision reduction gears are manufactured in several modifications according to the specification of the shaft and the case.

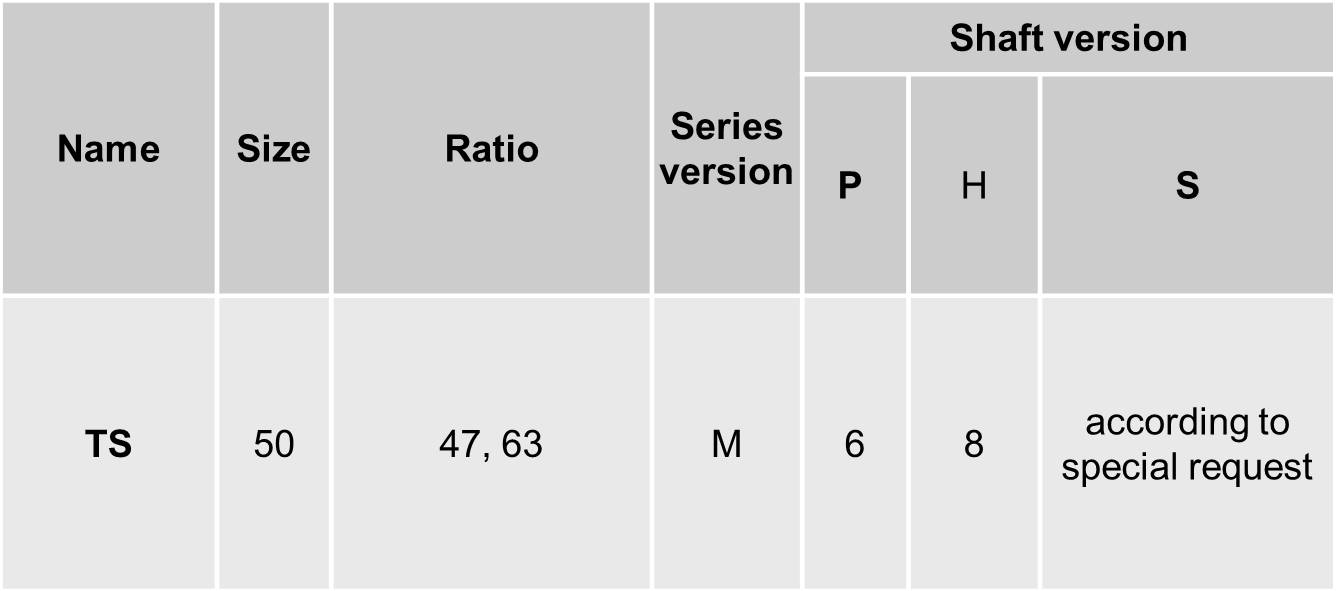

M series ordering specifications

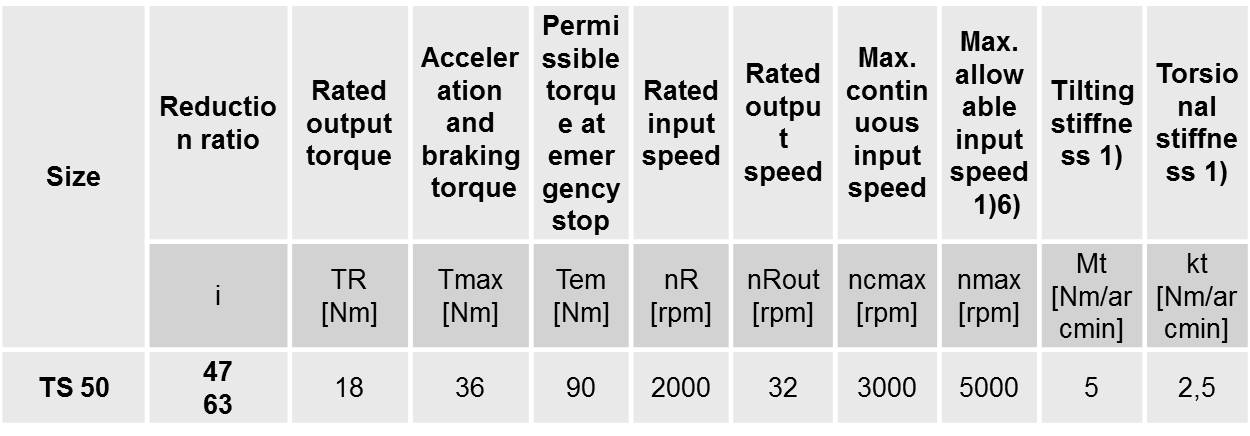

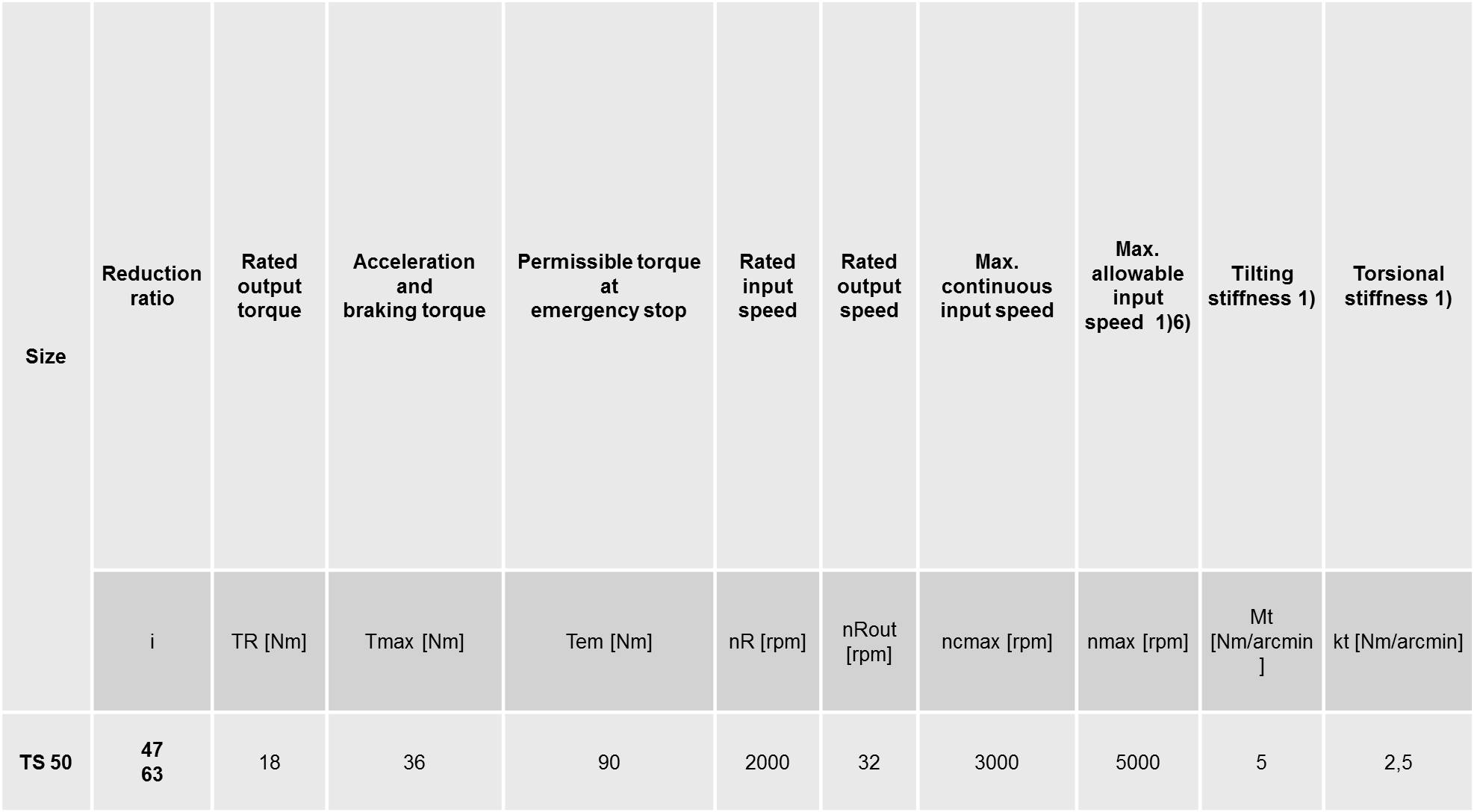

Rating table M series

RIGHT TO CHANGE WITHOUT PRIOR NOTICE RESERVED

1/ Mean statistical value.

2/ Load at output speed nRout=nR/i. for TS 50 M it is 32 [rpm].

3/ Tilting moment Mc max at Fa=0. If Fa≠0 see par.3.5.1.

4/ Axial force Fa max for Fr=0, Mc=0. If Mc≠0 par.3.5.1.

5/ Radial force Fr max for Fa=0. If Fa≠0 see par.3.5.1.

6/ At 50% ncmax (max input speed in cycle)

7/ Applies to standard version of the high precision reduction gear with shaft connected by a key-way.

8/ a2 - is the distance of the radial force centre from the front of the output flange [m].

Note:

Load values in table are valid for nominal life Lh=6000 [Hrs].

General Advantages of Spinea Gearboxes

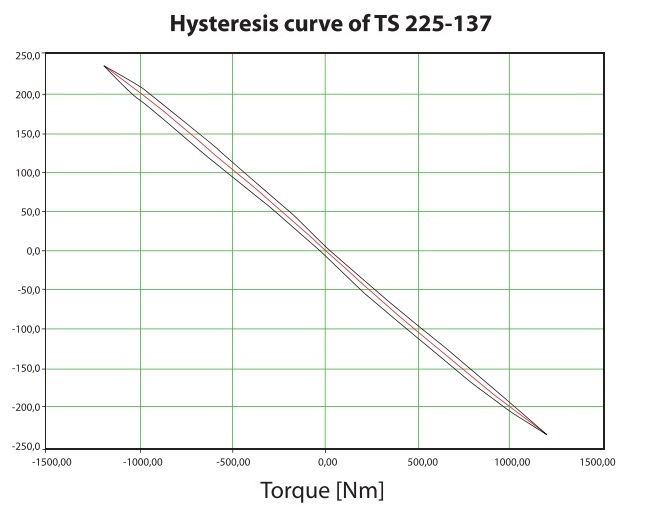

SPINEA PRODUCED TS225 VE TS245 SERIES WHICH HAVE < 0,5 ARCMIN

TS225 and TS245 series standardly have <0,5 arcmin.Below, you could find hysteresis curve of TS225 (i:137)

MAIN ELEMENTS OF TWINSPIN SERIES